Autocartoning

Continuous motion cartonators

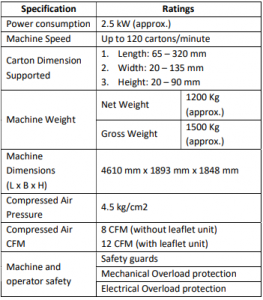

xtechnocrat continuous motion cartonators incorporate modern technical standards with high output and

reliability. It opens the pre-folded cartons, inserts products and closes the carton tucking in the flaps. It is

well suited to handle products such as tubes, bottles, vials, blisters, soaps, sachets, pouches etc. It can also

be used for other products because of the wide range of carton sizes supported. Optional equipment such

as leaflet insertion unit and online printing/debossing unit to enhance production capacity and features to

meet todays high-speed packaging demand is available. The machine offers extreme versatility in changing

over to different sizes with a need for minimal change parts and downtime. It also has several interlocking

features that minimize wastage of raw material like leaflets and cartons. Safety features that offer protection

for mechanical and electrical overloads are included in all models.

1. Continuous motion loading enables gradual and smooth product insertion.

2. Safety features to protect the machine against mechanical and electrical overloads.

3. Programmable operational time for key machine functions.

4. HMI enables fast and easy troubleshooting of issues reducing downtime.

5. Programmable user profiles to restrict HMI access based on user level.

6. Variable speed drive allows to match cartoning speed with upstream equipment such as a tube filling.

bottle filling or labelling machine

1. Pre-folded leaflet insertion unit, folding

and insertion unit.

2. Online printing or debossing with stereos.

3. TIJ/CIJ printing unit with/without printing

inspection system.

4. Safety guards with/without door switch

interlock.

5. Transfer systems for bottles, vials, tubes,

blisters etc. available.

6. Barcode/Pharmacode detection for carton

and leaflet.

7. Hot/cold glue applicator instead of tuck-in

8. CE certification of the machine.

9. 21 CFR Part 11 Compliance.

Continuous motion cartonators

xtechnocrat continuous motion cartonators incorporate modern technical standards with high output and

reliability. It opens the pre-folded cartons, inserts products and closes the carton tucking in the flaps. It is

well suited to handle products such as tubes, bottles, vials, blisters, soaps, sachets, pouches etc. It can also

be used for other products because of the wide range of carton sizes supported. Optional equipment such

as leaflet insertion unit and online printing/debossing unit to enhance production capacity and features to

meet todays high-speed packaging demand is available. The machine offers extreme versatility in changing

over to different sizes with a need for minimal change parts and downtime. It also has several interlocking

features that minimize wastage of raw material like leaflets and cartons. Safety features that offer protection

for mechanical and electrical overloads are included in all models.

1. Continuous motion loading enables gradual and smooth product insertion.

2. Safety features to protect the machine against mechanical and electrical overloads.

3. Programmable operational time for key machine functions.

4. HMI enables fast and easy troubleshooting of issues reducing downtime.

5. Programmable user profiles to restrict HMI access based on user level.

6. Variable speed drive allows to match cartoning speed with upstream equipment such as a tube filling or

bottle filling machine.

1. Pre-folded leaflet insertion unit, folding

and insertion unit.

2. Online printing or debossing with stereos.

3. TIJ/CIJ printing unit with printing inspection

system.

4. Safety guards with/without door switch

interlock.

5. Transfer systems for bottles, vials, tubes,

blisters etc. available.

6. Barcode/Pharmacode detection for carton

and leaflet.

7. CE certification of the machine.

8. 21 CFR Part 11 Compliance.

Continuous motion cartonators

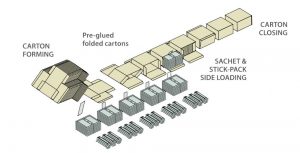

DELTA 200 CONTINUOUS MOTION CARTONER. 200 CARTONS PER MINUTE IN JUST 1,6 METERS

Delta 200 are continuous motion cartoning machines for packaging of sachets and tubes in cartons starting from pre-glued cartons.Delta 200 series machines combine the advantages of reduced overall dimensions with greater solidity, reliability and high throughput.

Double Balcony (cantilever) frame construction allows operator access from front and rear of the machine and simple cleaning, maintenance, inspection and size changeover operations.

Differentiated placement of mechanical and drive units as well as separated product handling are basis for a clean machine, assuring safety when executing lot changes, also preventing carton dust and fragments from falling onto main drive components.

Delta 200 cartoners have a completely enclosed structure with safety devices on all the opening parts to ensure overall protection and compliance with all the current safety regulations.

It combines proven technology with new features such as positive carton opening and innovative, simply and positive carton transport, ensuring aesthetically impeccable packaging.

- Automatic product feeders

- Automatic leaflet or booklet feeders

- Barcode, part number and camera for vision system

- Wide selection of coding systems: Ink jet, Laser or Ink/Embossing

- Glue or tuck in carton closure

- Possibility to install an automatic pre-folded leaflet feeder, or a leaflet folder GUK unit, always in an easy and accessible position for the operator

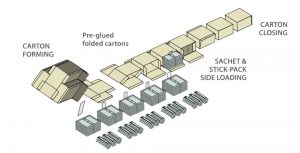

INTERMITTENT MOTION CARTONER

Delta 130 are intermittent motion cartoning machines for packaging of stacked sachets in pre-glued cartons. Delta 130 series machines combine the advantages of reduced overall dimensions with greater solidity, reliability and high throughput.

Double Balcony (cantilever) frame construction allows operator access from front and rear of the machine and simple cleaning, maintenance, inspection and size changeover operations.

Differentiated placement of mechanical and drive units as well as separated product handling are basis for a clean machine, assuring safety when executing lot changes, also preventing carton dust and fragments from falling onto main drive components.

Delta 130 cartoners have a completely enclosed structure with safety devices on all the opening parts to ensure overall protection and compliance with all the current safety regulations.

It combines proven technology with new features such as positive carton opening and innovative, simply and positive carton transport, ensuring aesthetically impeccable packaging.

- Automatic product feeders

- Automatic leaflet or booklet feeders

- Barcode, part number and camera for vision system

- Wide selection of coding systems: Ink jet, Laser or Ink/Embossing

- Glue or tuck in carton closure

- Possibility to install an automatic pre-folded leaflet feeder, or a leaflet folder GUK unit, always in an easy and accessible position for the operator

Vertical Cartoning Machine

1. Automatic carton erection-manual product insertion.

2. Automatic leaflet insertion available (optional).

3. Safety features to protect the machine against mechanical and electrical overloads.

4. Interlocking operation between product detection, leaflet placement, carton placement and pusher

operation

a. If carton is not placed, the leaflet insertion shall be by-passed.

5. Programmable operational time for key machine functions.

6. HMI enables fast and easy troubleshooting of issues reducing downtime.

7. Programmable user profiles to restrict HMI access based on user level.

8. Variable speed drive allows to match cartoning speed with available human resources.

9. Empty carton rejection system comes pre-installed with this machine.

1. The machine picks up pre-folded cartons and erects them automatically.

2. If a leaflet unit is installed, it shall automatically insert a leaflet in the carton if the carton was erected.

3. The machine shall close the bottom flap and tucks it in.

4. The operator now needs to insert the product into the carton.

5. Once the product is inserted, there is a pusher to push the product completely in the box in case the operator does not push the product in completely.

6. The top flaps are closed in the last step.

7. At the exit, there is an empty carton rejection system. If the carton is empty, it shall be pushed out in a different direction than the normal exit direction.

1. Pre-folded leaflet insertion unit.

2. Safety guards with/without door

switch interlock.

3. Online printing unit.