SCARA

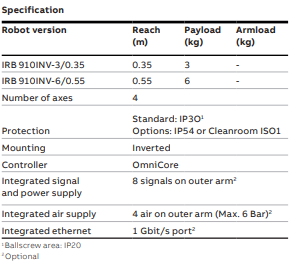

IRB 910INV

Ceiling-mounted SCARA increases assembly flexibility

Fast, cost-effective and, because it‘s from ABB, accurate. The ceiling mounted SCARA offers space savings and increased assembly flexibility.

Ceiling-mounted SCARA increases the working area

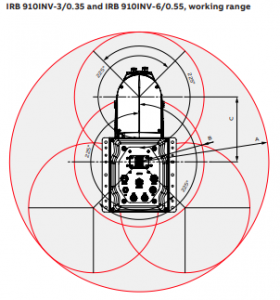

ABB’s new ceiling-mounted IRB 910INV robot is designed to increase the space efficiency and flexibility of each cell and support the performance of complex tasks even in confined spaces. By mounting the IRB 910INV on the ceiling, manufacturers can increase the space efficiency and flexibility of each cell and do more complex tasks even in confined spaces. Moreover, the IRB 910INV robot can collaborate with other robots and machines, substantially boosting productivity.

Best-in-class motion control for faster cycle times

Powered by an ABB OmniCoreTM controller, the IRB 910INV robot offers the best-in-class motion control for repeatable point-to-point accuracy during pickand place, assembly, and testing applications. This includes electronics small parts assembly tasks such as screw driving, component inserting or mounting, and automated quality control inspections.

IP54 and Cleanroom ISO 1 are available options. IRB 910INV is ISO 14644-1 certified for use in cleanroom applications in, for example, the semiconductor industry.

Delivers excellent performance and

comprehensive functionalities

When designing the IRB 910INV robot, ABB wanted to emphasize speed and accuracy. Although small in size, the ceiling-mounted IRB 910INV robot offers the same high performance and functionalities as other ABB small robots, specifically, superior path control, accuracy, and a small footprint.

- Ceiling-mounted SCARA offers space savings

and increased flexibility - Class-leading repeatable accuracy with ABB’s

superior motion control - Fast cycle times for increased throughput and

productivity - Equipped with up to 16 I/O for more sophisticated/

complex applications

- Assembly & Testing

- Material handling

- Picking & Placing

- Screw driving

- Rubber insertion

Physical

- Dimensions robot base 200 x 200 mm

- Weight IRB 910INV-3/0.35 19 kg

- Weight IRB 910INV-6/0.55 22 kg

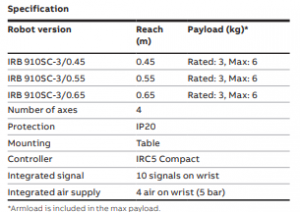

IRB 910SC

The IRB 910SC (SCARA) is fast, cost-effective and, because it‘s from ABB, accurate. In designing its Selective Compliance Articulated Robot Arm (SCARA), or IRB 910SC, ABB has delivered a single arm robot capable of operating in a confined footprint. ABB’s SCARA is ideal for the Small Parts Assembly, Material Handling and parts inspection.

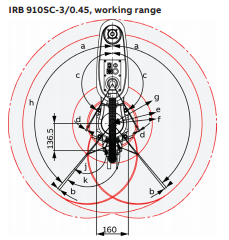

With a maximum payload of 6 kg, the IRB 910SC is available in three configurations (IRB 910SC –3/0.45, IRB 910SC – 3/0.55m, and IRB 910SC – 3/0.65.).

All are modular by design, with different linking arm lengths and have individual reaches of 450 mm, 550 mm and 650 mm, respectively.

All members of the SCARA family are tabletop mountable.

ABB’s SCARA family is designed for a variety of general-purpose applications such as tray kitting, component placement, machine loading/unloading and assembly.

These applications require fast, repeatable and articulate point-to point movements such as palletizing, depalletizing, machine loading/unloading and assembly.

ABB’s SCARA family is ideal for customers requiring rapid cycle times, high precision and high reliability for their Small Part Assembly applications and for laboratory automation and prescription drug dispensing.

- Table top mountable

- Ease of integration

- Custom interfaces

- Modular design

- Short cycle times which achieved by high speed

- High precision which is achieved by superior

motion control - Superb reliability due to reuse and standard

proven components.

Electrical Connections

- Supply voltage – 200-600 V, 50/60Hz

- Transformer rating – 3.0 kVA

Power - consumption – 220 W

Physical - Footprint 160 x 160 mm

- Weight IRB 910SC -3/0.45 24.5 kg

- Weight IRB 910SC -3/0.55 25 kg

- Weight IRB 910SC -3/0.65 25.5 kg

Environment Ambient - temperature for mechanical unit

Manipulator during operation + 5°C (41°F) to + 45°C (113°F) - Complete robot during

transportation and storage

– 25°C (-13°F) to + 55°C (131°F) - For short periods (not

exceeding 24 hours)

up to + 70°C (158°F) - Relative humidity Max. 95% at constant temperature

- Noise level < 70 dB