Tube Filling & Sealing Machine

Our rotary style tube filling machines are designed to be as compact as possible, while providing all essential features

required in order to meet the challenges and stringent demands of the pharmaceutical industry. The design is also

capable of handling applications in the cosmetics industry. Our tube filling machines have the capability to handle

materials of various viscosities ranging from creams, ointments and pastes to gels like facewash. Smooth and

accurate filling is an essential characteristic of our machine. Safety features that offer protection for mechanical and

electrical overloads are included in all models.

1. Tube Cleaning with compressed air and vacuum.

2. Automatic Tube feeding.

3. Automatic Tube orientation.

4. Material Filling.

5. Tube Heating.

6. Tube Sealing.

7. Tube Cutting.

8. Tube discharging.

1. Chilling Block for improved sealing quality.

2. Hopper level maintenance system.

3. Tube cleaning system with compressed air and vacuum.

4. Link mechanism to link with Cartoning machine.

5. Safety guards with/without door switch interlock.

6. Jacketed hopper with stirrer.

7. Online printing with CIJ printers.

1. Compact design and simple operation.

2. Compliant with cGMP and WHO standards.

3. S.S. 316 and Teflon contact parts.

4. No-tube-no-fill mechanism.

5. Automatic tube orientation.

6. Nozzle shut-off mechanisms to prevent dripping.

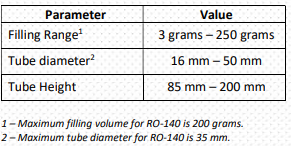

7. Accurate filling up to ±1% of the filling volume.

8. System to cut-off the rat-tail from the filling nozzle by air

burst.

9. Interlocks to ensure operator and machine safety.

10. Easy to clean and maintain.